SEM-EDX PARTICLE ANALYSIS

Phenom ParticleX Enables Automated High-Throughput Analysis

Phenom ParticleX

Particle Analysis in Table Format

The system offers complete integration of microscopic imaging (SEM) and elemental analysis (EDX) in one software and is therefore ideally suited for automatic particle analysis and fast manual SEM-EDX analysis.

Specifications

- Automation for particles & manual SEM-EDX analysis

- XL sample chamber, 4 x 47 mm filters or 36 x 12 mm stubs

- Motorized stage XY 100 mm x 100 mm

- Long-lasting CeB6 filament, approx. 2000 hours

- Variable high voltage 4.8-20.5 kV

- Integrated SDD EDX detector, active area 25 mm²

- High vacuum and variable low vacuum

- BE detector for particle analysis, optional SE detector

- Magnification up to 100,000x, additional 12x digital zoom

- Integrated light microscope, magnification 3-16x

Perception Software

Designed for Maximum Throughput

Dynamic Beam Control

The search area is scanned point by point with the electron beam, and empty areas are scanned quickly. This saves up to 98% of the time required for imaging. Perception only switches to measurement mode when a particle is detected.

Microscopic Image

In preparation for the granulometric analysis, the particle is examined under a high-resolution microscope. The excellent image quality of the ParticleX gives the user an optimal impression of the morphology of the particle.

Granulometric Analysis

By segmenting the microscopic image with a threshold value, a geometric binary model of the particle is generated. This model is used to determine the relevant particle dimensions.

Classification of the Material

While the image is being taken, the elements and their weight proportions are determined using X-ray element spectroscopy (EDX). The material is classified using a hierarchical database.

They don't care about anything

Reproducible results independent of the operator can only be achieved through automation. The Perception software uses automatic routines to ensure that the system is always optimally configured. The user does not have to worry about anything:

- Auto video level and threshold

- Auto focus and degauss

- Auto EDX calibration

- Auto gun alignment

- Auto vacuum control

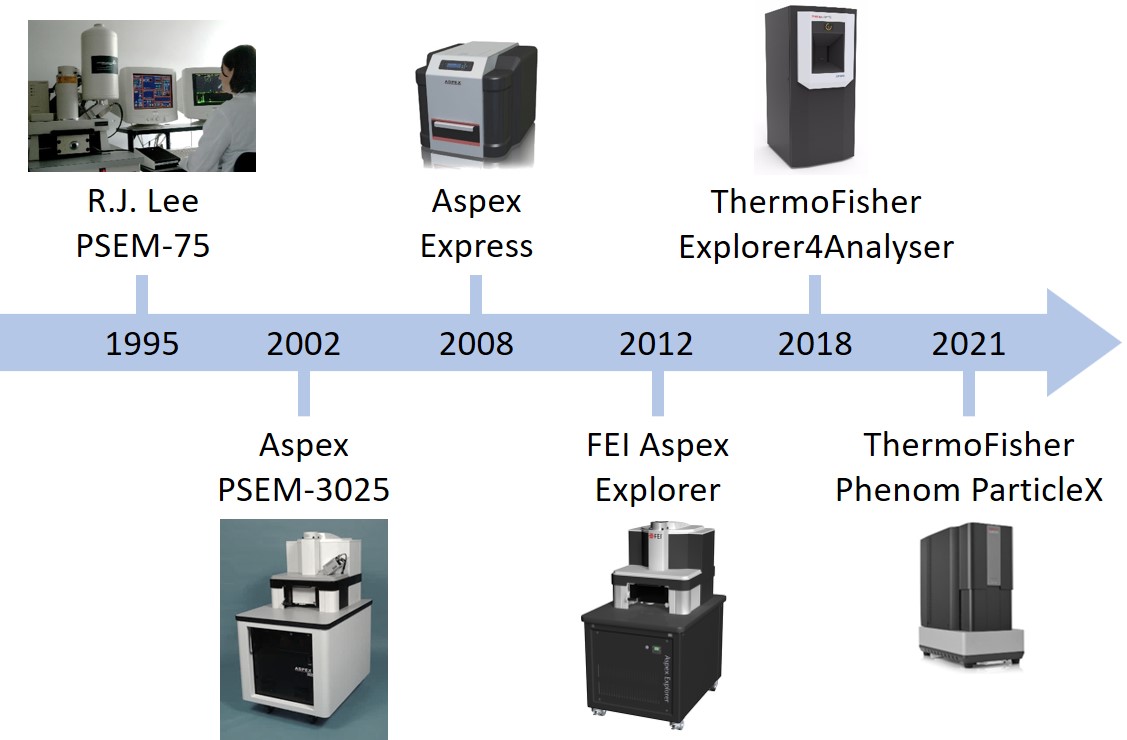

History of Perception

The development of automatic SEM-EDX particle analyzers dates back to 1995, when Richard J. Lee developed the first PSEM with Perception under MS-DOS for steel inclusion analysis. Since then, the software platform has been continuously developed and adapted to the requirements of new applications.

Phenom ParticleX – this is the perfect symbiosis of the well-known Perception software for particle analysis with the robust Phenom SEM-EDX tabletop devices from Thermo Fisher Scientific. The instrument counts and measures particles and classifies the material fully automatically. The compact devices are used in industrial testing laboratories, in research and in forensic laboratories for particle and inclusion analysis.

Highlight applications

Technical Cleanliness

Particle analysis in automotive and medical technology involves determining the size and material of foreign particles in order to estimate the risk of failures and damage and to determine the origin of the contamination.

Gunshot Residue Analysis

In forensic science, the reliable detection of gunshot residue on the hands and clothing of suspects is necessary for the proof of firearm use. The so-called gun shot residue (GSR) consists of characteristic elements that can be detected using SEM-EDX particle analysis.

Steel Inclusion Analysis

To determine the quality of the steel, the number, size and chemical composition of the non-metallic inclusions (mostly oxides) are examined. A representation of the results in ternary diagrams provides a quick insight.

Powder for Battery Production

Battery performance is significantly influenced by the particle size, morphology and composition of the NMC powder. Equally relevant are metallic and hard foreign particles that can damage the battery cell separator.

Additive Manufacturing

The quality of the powder is crucial for error-free 3D printing of components. Powder analysis examines the size, shape, agglomeration and oxidation of the metal particles. Investing in an SEM-EDX with particle automation is particularly worthwhile for larger production lines.

Stages, Holders & Accessories

XL sample chamber as insert

Simply remove the sample chamber and load it easily – this is only possible with the Phenom ParticleX. The sample chamber of 100 mm x 100 mm x 65 mm can accommodate even large and bulky samples, usually without complex preparation.

Holder for 47 mm membranes

During the cleanliness analysis, the foreign particles are prepared for examination on 47 mm membranes. Four filter positions allow automatic operation with high throughput. This makes your ParticleX a real workhorse. There is an optional holder for nine 25 mm membranes.

Universal holder for stubs & samples

The standard stage is motorized in XY (100 mm x 100 mm). The height is adjusted by the user via a manual Z-axis (65 mm); motorization is optionally available. The holder offers space for several samples and complete components or up to 36 x 12 mm stubs in the hole grid.

Nebula Particle Dispenser

The Nebula particle dispenser provides a standard method for the uniform dispersion of dry powder on stubs. The process guarantees a homogeneous distribution on the surface, which facilitates SEM-EDX analysis.