We are hiring: Office worker (m/f/d) part-time

To support our secretariat, we are looking for a dedicated office worker (m/f/d) on a part-time basis (up to 501 hours). Working hours by arrangement in the mornings and afternoons.

To support our secretariat, we are looking for a dedicated office worker (m/f/d) on a part-time basis (up to 501 hours). Working hours by arrangement in the mornings and afternoons.

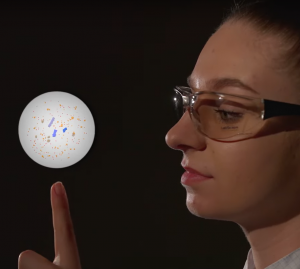

Anyone who has samples tested for cleanliness relies on reliable testing and precise determination and representation of the particles contained. With our Particle Browser, we offer you software for follow-up checks and revisions to verify analysis results and to identify and correct possible measurement errors.

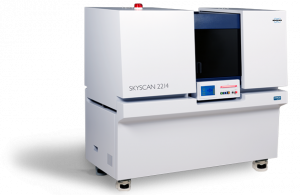

As part of the DELFIN joint project, we have acquired a new type of X-ray microscope (“nano-CT”) to examine the electrode structure of a modern lithium solid-state battery using 3D imaging.

To support our technical customer service we are looking for a dedicated service technician in the office and field service, full-time or part-time (80%).

Customers have repeatedly asked us whether we can determine the residual moisture in coolers. We have now equipped our laboratory with a device for analyzing residual moisture and offer this test as standard. We have already successfully carried out the first tests on behalf of customers

In addition to our daily analysis work, researching and developing new processes is particularly exciting for us. We are therefore very pleased that we are able to work on the DELFIN joint project and thus on an interesting topic - the development of solid-state batteries.

Please note that our testing laboratory will be closed from December 27th, 2023 to January 5th, 2024 and our secretariat will only be accessible to a limited extent during this time.

Our customer Dr. Anton Windfelder from the Justus Liebig University of Giessen has published an impressive study on the intestinal tract of the tobacco hornworm caterpillar (Manduca sexta). This animal serves as a model system for ecotoxicology, immunology and intestinal physiology.

Our particle scanner for quick and easy cleanliness checks according to VDA-19.1 and ISO-16232 has received an update. The new hardware is even more compact and delivers razor-sharp images of unwanted residual dirt particles with a resolution of 5 µm/pixel.