SKYSCAN MICRO & NANOTOMOGRAPHY

Get Unique Insights into the Interior of Your Samples

Desktop Micro-CT Instruments

The Micro-CT desktop series from Bruker impresses with its maintenance-free, robust design and simple operating concept. The devices are equipped with a comprehensive software package for data analysis and visualization; updates are free of charge. The devices can optionally be equipped with a sample changer, tensile-compression test and sample temperature control.

Bruker X4 Poseidon

Desktop 3D X-ray microscopy platform

closed microfocus source reflection target 20-100 kV

or transmission target 20-110 kV, spot size 2 µm

Flat panel 7 Mpx, largest image field Ø 102 mm, height 186 mm

and/or detector sCMOS 16 Mpx, smallest voxel 0.2 µm

Free-field phase contrast extraction according to Paganin

SkyScan 1273

Desktop Micro-CT for Oversized Samples

Energy 40-130 kV, 39 W, closed tube

Detector CMOS flat panel 6 Mpx, smallest voxel 3.0 µm

Largest field of view Ø 250 mm, height 250 mm

Largest object Ø 300 mm, height 500 mm

In-Vivo Micro-CT Instruments

SkyScan in-vivo micro-CTs are characterized by the best resolution available on the market, even at a low radiation dose. The instruments are equipped with a complete biomonitor and can be used to analyze bones, vessels, lungs, heart, body fat and tumors in live animal studies. Due to the high resolution of up to 2.8 μm / voxel, the instruments can also be used in the analysis of preparations.

SkyScan 1276-CMOS in vivo

Micro-CT In-Vivo High Resolution & Quick

Energy 20-100 kV, 20 watts, closed tube

Detector sCMOS 16 Mpx, smallest voxel 2.8 μm

variable resolution through geometric magnification

Largest image field Ø 75 mm, length 310 mm

Fastest scan 3.9 sec, touchscreen interface

SkyScan 1278 in vivo

Micro-CT In-Vivo Economical

Energy 20-65 kV, 50 watts, closed tube

Detector CMOS flat panel 3 Mpx, smallest voxel 50 μm

Largest image field Ø 80 mm, length 200 mm

Fastest scan 7.2 sec, touchscreen interface

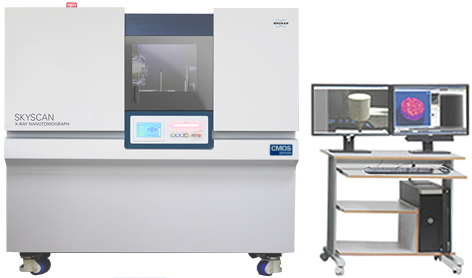

Nano-CT & X-ray microscopy

In addition to the compact desktop devices, the SkyScan series also features a 3D X-Ray microscope with Nano-CT resolution and optical magnification levels.

SkyScan 2214 CMOS

Multiscale Nano-CT for Highest Resolution & Large Samples

Energy 20-160 kV, 16 watts, open tube, micro/nano focus

Up to four detectors automatically switchable:

sCMOS 15 Mpx for highest magnification

sCMOS 16 Mpx for medium magnification

sCMOS 16 Mpx with large image field

CMOS Flat Panel 6 Mpx for large & dense samples

smallest voxel 60 nm with sCMOS 15 Mpx

Largest image field Ø 140 mm, height 130 mm

Largest object Ø 300 mm, height 400 mm

Free-field phase contrast extraction according to Paganin

Air-bearing stage

With the SkyScan series, Bruker microCT offers high resolution and reliable X-Ray microtomography systems for academia and industry. Your sample's internal structure can be analyzed non-destructively in 3D down to the sub-micron scale.

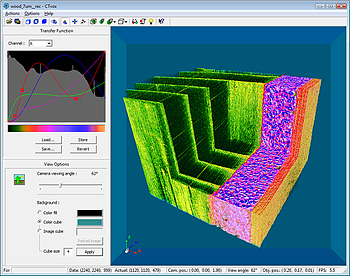

Software & Biomonitor

SkyScan 3D.SUITE from Bruker

All systems are delivered with the in-house software package 3D.SUITE. The package offers a vast variety of functions and impresses with its user-friendliness.

– Instrument control and data recording

– GPU reconstruction including drift correction

– Reconstruction of standard and spiral scans

– Reconstruction of high-aspect ratio scans

– Phase contrast extraction according to Paganin

– Visualization in 2D, 3D volume rendering

– Morphometric image analysis

– Automation via scripts, batch manager

– Updates free of charge, multiple license included

Monitor for in-vivo scans

Small animals can repetitively be examined during longitudinal studies using SkyScan in-vivo instruments. Bruker microCT has developed a special biomonitoring system, which enables sustainment, monitoring and scan synchronization.

– Animal bed as a closed cassette with gas anesthesia

– including warm air flow and temperature sensor

– Camera and motion monitor

– Biomonitor for lung and heart function (ECG)

– On-screen X-ray dosimeter in real time

– intrinsic movement trigger from x-ray images

– additional sensoric trigger signals

– prospective and retrospective synchronization

– 4D analysis (XYZ+T)

sample stages & autosamplers

Special Sample Stages

Stages for mechanical in-situ experiments

Tensile/compression, three models up to 42/220/440 N

High-load compression test, two models up to 2200/4400 N

Force measurement accuracy ±1%

Experimental protocal automated using a script

Stages for in-situ temperature experiments

Holder equipped with Peltier element

Cooling down to -15 °C, heating up to +80 °C

Temperature control accuracy ± 1 K

- Compatible with X4 Poseidon, SkyScan 1273 & 2214

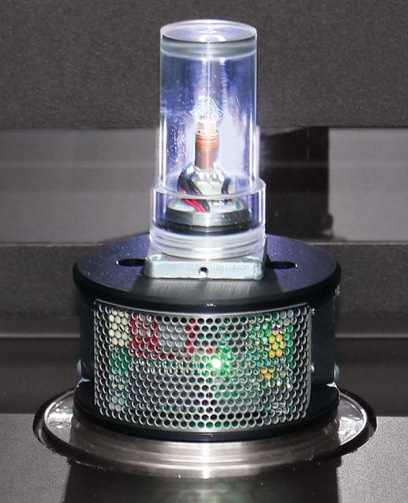

Highest possible throughput

A robot tongs grabs the sample holder with the test object and places it on the rotating stage. Data acquisition and sample changes are completely automated, protocols can be stored separately for each sample, and the presence of an operator during analysis is not required.

Depending on the model, up to 16 samples can be installed simultaneously in the carousel. Samples that have already been scanned can be identified by status LED and can be replaced with new samples at any time, even during the ongoing scan.

- Compatible with SkyScan X4 Poseidon