CLEANLINESS ANALYSIS - OVERVIEW

Screening for Technical Cleanliness According to VDA-19.1 & ISO-16232

Step 1

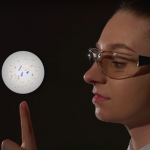

Extraction of Surface Contamination

Initially, residual particles are extracted from the component surface by rinsing, spraying or ultrasound, and transferred to a liquid medium (fluid). The solid particles are prepared onto a membrane by vacuum filtration, enabling further analysis.

Initially, residual particles are extracted from the component surface by rinsing, spraying or ultrasound, and transferred to a liquid medium (fluid). The solid particles are prepared onto a membrane by vacuum filtration, enabling further analysis.

Step 2

Gravimetry of Residual Oil Mass

Selective evaporation separates the liquid flushing medium from oils, lubricants and other processing additives, which are subsequently weighed separately. The residue weight characterizes the degree by which component surfaces are contaminated with oil and fats.

Selective evaporation separates the liquid flushing medium from oils, lubricants and other processing additives, which are subsequently weighed separately. The residue weight characterizes the degree by which component surfaces are contaminated with oil and fats.

Step 3

Gravimetry of Particle Mass

The easiest way to quantitatively evaluate contamination by residual particles is to weigh the membrane before and after preparation. The difference between the two measurement results is the particle mass. For simple cleanliness requirements, this value is often sufficient.

The easiest way to quantitatively evaluate contamination by residual particles is to weigh the membrane before and after preparation. The difference between the two measurement results is the particle mass. For simple cleanliness requirements, this value is often sufficient.

Step 4

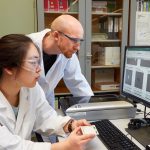

Measurement of Particle Number and Size

Particle number and size are determined by analyzing the membrane with a scanner or light microscope. Due to their high working speed, scanners are not only suitable for standard analysis according to VDA-19.1 & ISO-16232, but also for process control of component cleanliness.

Particle number and size are determined by analyzing the membrane with a scanner or light microscope. Due to their high working speed, scanners are not only suitable for standard analysis according to VDA-19.1 & ISO-16232, but also for process control of component cleanliness.

Step 5

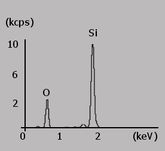

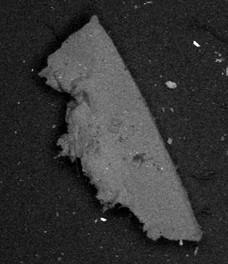

Granulometry with Material Typification

Technical sublime is the analysis by means of automated scanning electron microscopy and elemental analysis (SEM-EDX). In addition to number and size, this method also provides an individual typification of materials, hence allowing the particles' origin to be precisely constrained.

Technical sublime is the analysis by means of automated scanning electron microscopy and elemental analysis (SEM-EDX). In addition to number and size, this method also provides an individual typification of materials, hence allowing the particles' origin to be precisely constrained.

Step 6

3D Particle Measurement

In cleanliness testing, the trend is towards spatial measurement of the particles. The thickness and volume of the individual particles are important quantities that are determined by X-ray microtomography.

In cleanliness testing, the trend is towards spatial measurement of the particles. The thickness and volume of the individual particles are important quantities that are determined by X-ray microtomography.