According to a study by the Fraunhofer Institute UMSICHT in Oberhausen, vehicle tire wear is the world's largest source of microplastic. On average, a car tire weighs 1 to 1.5 kg less at the end of its life than at the beginning. This difference is largely released into the environment as microplastic particles.

In order to answer the question of the whereabouts of microplastic particles from tire abrasion, new analysis methods are urgently needed to reliably detect and count these particles. We have carried out a pilot study to explore the possibilities of automatic SEM-EDX analysis when quantifying tire abrasion in environmental samples.

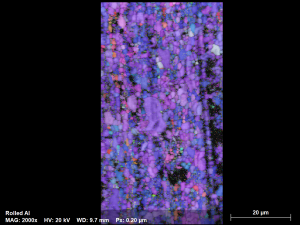

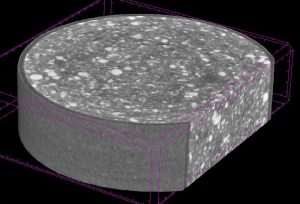

Our project partner provided us with a sample taken from a real street. We prepared a portion of this particulate sample by means of vacuum filtration on a membrane.

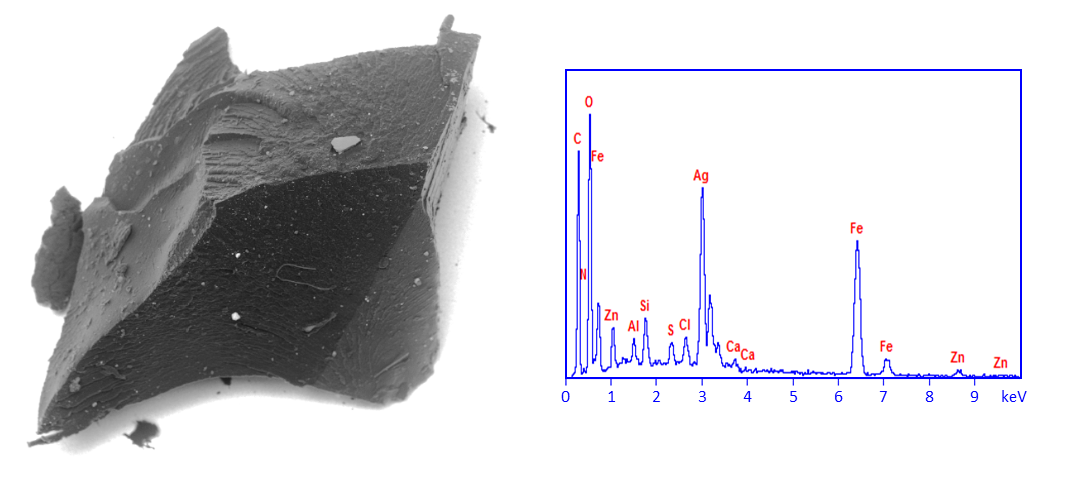

In order to find the tire abrasion particles in the sample, we first took reference particles from real tires and analyzed them by SEM-EDX The following shows a microscopic image and an element spectrum of a tire rubber particle on a silver membrane from the reference sample.

A comparison of the abrasion of different brands has shown that tire rubber contains not only carbon (C), oxygen (O) and nitrogen (N), but also sulfur (S). Depending on the manufacturer, mineral and metallic fillers (Si, Ca, Al, Fe, Zn) are also added to define the hardness of the rubber. This chemical "fingerprint" is unique and allows the precise differentiation of tire wear from other inorganic and organic components that occur in street sweepings.

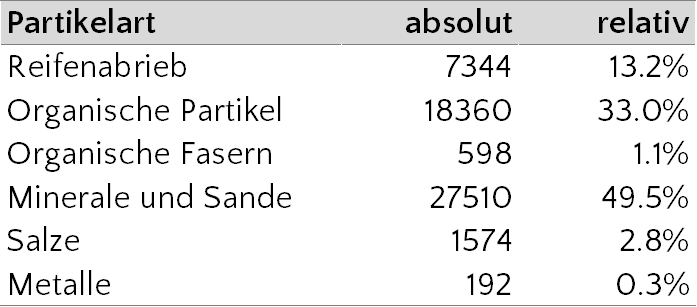

With this knowledge, we successfully identified and quantified the portion of tire wear in the sample by automated SEM-EDX particle analysis. In the following table we show exemplary results of the sample, the analysis shows all particles larger than 5 µm.