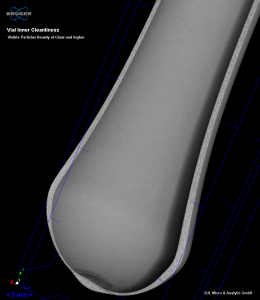

Particle Browser: A new tool for post-processing of SEM-EDX particle analysis

Anyone who has samples tested for cleanliness relies on reliable testing and precise determination and representation of the particles contained. With our Particle Browser, we offer you software for follow-up checks and revisions to verify analysis results and to identify and correct possible measurement errors.