The determination of technical cleanliness according to VDA-19.1 and ISO-16232 has become an integral part of quality control and failure analysis - because the cleanliness of components is crucial for the quality and flawless functioning of the product. In addition to particles, film contamination is a problem, as the following example from quality assurance in the production of electrical transmission systems shows.

Our customer had repeated complaints about malfunctions in automatic transmission systems. After internal tests, the failures could be attributed to the malfunctioning of a brake. A defect in the mechanics was quickly ruled out, thus raising the suspicion that residual contamination on the functional surfaces could impair the braking effect. Our test laboratory examined the cleanliness of the brake components and we were able to give the customer specific advice on how to solve the problem.

Our team disassembled both functional and faulty brake components and extracted the residual contamination from the functional surfaces using solvents. Initially, the particulate contaminants were filtered from the solvent onto a membrane and analyzed with the help of automatic SEM-EDX analysis. With this method, number, size and particle composition were individually determined. The result of our SEM-EDX analysis showed that the amount of particles on both brakes was equally small and unspecific. In particular, no abrasive particles such as silicates, corundum or other grinding residues were found. With this result, we were able to rule out particulate contamination as the cause of failure.

In the next step, we examined the surface tension of the functional surfaces with test ink pens and were able to identify that there was a minor filmic contamination on the faulty brake components. But where did this oily contamination come from and how could it get into the braking mechanism?

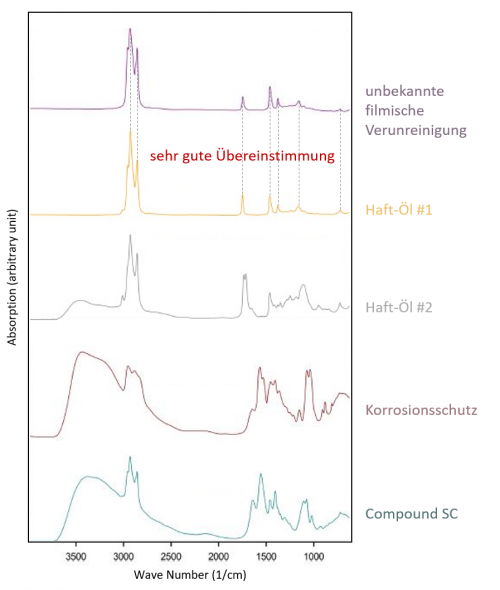

To answer this question, we selectively destilled the solvent from the rinsing medium using a rotary evaporator. The oily impurity remained as residue and was then analzyed with Fourier-Transform-Infrared-Spectrometry (FTIR). The customer provided us four reference samples from the production as potential "suspects", which we compared with the unknown filmic contamination.

The spectral comparison indeed showed good agreement with one of the reference substances. It was an adhesive oil that was used in a neighboring production step and unintentionally got transfered into the brake components. With this knowledge, the customer was able to quickly resolve the problem and permanently eliminate the malfunctions.

You can find out more about the molecular spectroscopy method on our website. If you would like to carry out similar studies with us, we look forward to hearing from you.