Bearing shells have the function of rolling and supporting rolling elements. In four-stroke engines, for example, the connecting rod that connects the piston to the crankshaft rotates in a bearing. This is lubricated with oil, which reduces friction and thus wear. However, the lubricant contains various residual contaminant particles that can become lodged in the bearing shell.

In the past, the bearing shells were usually coated with lead. As a soft metal, it has the advantage that it can absorb hard dirt particles such as aluminum oxide, silicon dioxide or steel and thus render it harmless. Due to the EU ban on the use of lead, manufacturers of bearing shells must resort to other soft materials, such as tin, for the coating of these components.

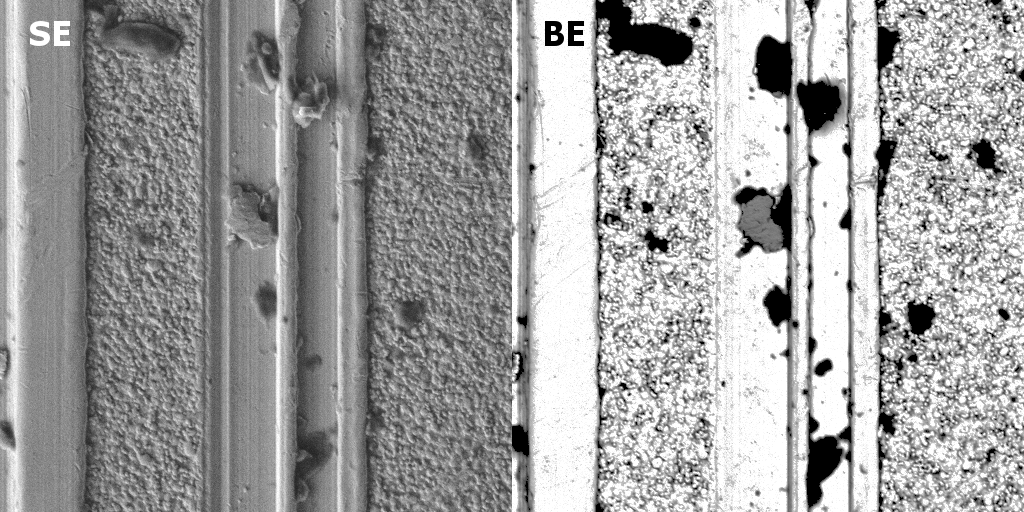

In our laboratory, we test the quality and wear of the bearing shells and examine to what extent hard particles can be embedded. With this we support the manufacturers in the development of new bearing coatings. The image (see above) was taken with an electron microscope (SEM-EDX) and shows the section of a bearing shell in which hard steel particles (iron-chromium) are pressed. Our laboratory is able to prepare a complete bearing shell and to count and chemically characterize the impressions over the entire tread.

Find out about the SEM-EDX systems from FEI-Aspex as well as our accredited analysis service.