New procedure established in the test laboratory: Analysis of the residual moisture of coolers

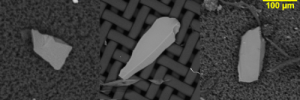

Customers have repeatedly asked us whether we can determine the residual moisture in coolers. We have now equipped our laboratory with a device for analyzing residual moisture and offer this test as standard. We have already successfully carried out the first tests on behalf of customers