Development of Modern Medicine Supported by Microtomography

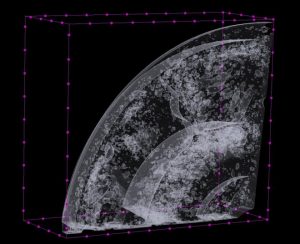

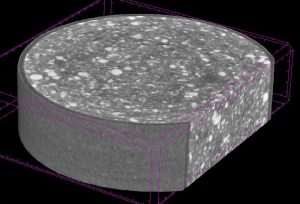

A medication, for example a painkiller, should work reliably and always release the active ingredient within a certain period of time. A decisive factor for this is the active ingredient content and reproducible release kinetics. With a micro-CT we can scan tablets non-destructively.