The quality standards in the processing of aluminum castings are very high. Especially in the automotive and aerospace industries, these parts must be extremely resilient, processing errors would endanger safety and longevity.

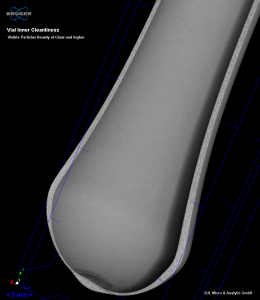

For the quality control in the industry, the use of X-ray computed tomography has been proven in recent years. This is used on the one hand for the metrological examination of components: internal geometries can thus be tested non-destructively and the dimensions of the components can be controlled.

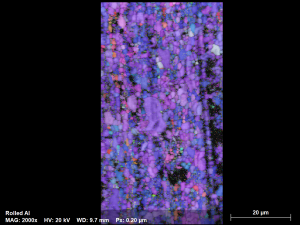

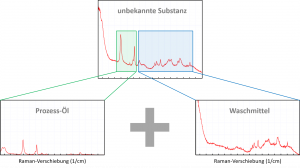

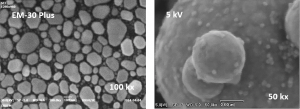

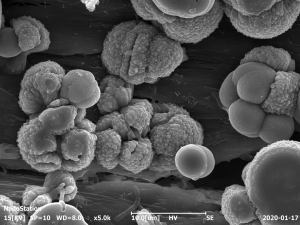

On the other hand, microtomography is used in microstructure analysis and the identification of defects. For example, occur at joints or joints in laser welding or even during the assembly of components errors. Cold deformations can lead to pores and cracks in the material, in the casting of components beyond cavities, so-called voids, arise inside.

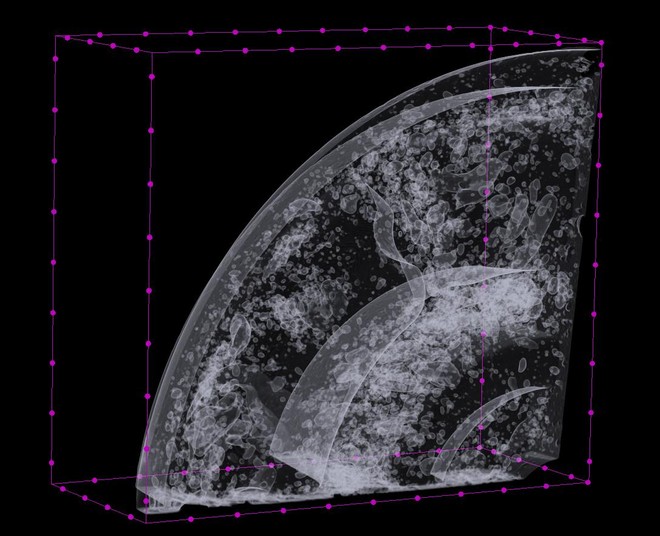

The following film shows the 3D image of an aluminum casting by means of a SkyScan tabletop model 1173 with a resolution of 28 μm / voxel. The voids that have formed during the casting process of this component are clearly visible. These arise when the material can not optimally flow during cooling and thereby the cavities are not sufficiently filled. The result is notch effects and thus the porosity of the casting.

Find out about the SkyScan devices from Bruker microCT and about our accredited analysis service.