WHAT IS TECHNICAL CLEANLINESS?

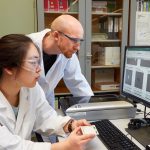

Basics of Component Cleanliness Inspection

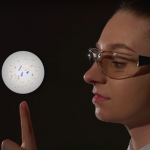

Particle Contamination

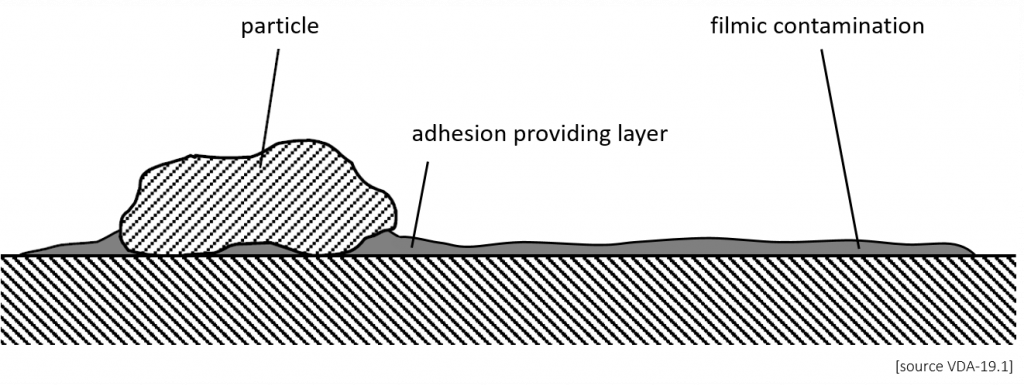

Particle contamination refers to solid particles and filmic contaminants that remain on a component's surface. Particle contamination can be generated during processing, or may be introduced via vendor parts, packaging and logistics.

Residual particles are introduced into engines or gearboxes during assembly. Especially hard, inorganic particles cause severe damage and drastically shorten a product's lifetime. Filmic impurities impede subsequent coating processes.

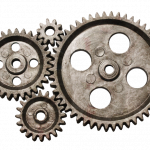

Technical Cleanliness

Technical cleanliness is defined by the amount of residual contaminates on the surface of a component. In order to describe the state of cleanliness, residual contamination and the number, size and composition of the particles are determined. In practice, the customer will define the threshold values for component contamination. The supplier has to comply with these limits and is responsible for regular test measurements.

Hardness Classes of Impurities

Minerals

The hardest residual contaminants are minerals like corundum, silicon carbide and sand. Most of these particles originate from surface treatment processes, such as grinding, tumbling or honing. Mineral particles are typically very small and light gray, thus resulting in weak contrasts, which is why they can not be reliably detected with the light microscope.

The hardest residual contaminants are minerals like corundum, silicon carbide and sand. Most of these particles originate from surface treatment processes, such as grinding, tumbling or honing. Mineral particles are typically very small and light gray, thus resulting in weak contrasts, which is why they can not be reliably detected with the light microscope.

Metals

The hardness of a metallic particle strongly depending on its material. Steels are hard, non-ferrous metals are rather soft. Residual metallic particles usually come directly from the manufacturing process. Steel particles are often corroded and lack a metallic gloss, which is why they are classified as non-metallic in the light microscope. SEM-EDX is recommended for a reliable detection.

The hardness of a metallic particle strongly depending on its material. Steels are hard, non-ferrous metals are rather soft. Residual metallic particles usually come directly from the manufacturing process. Steel particles are often corroded and lack a metallic gloss, which is why they are classified as non-metallic in the light microscope. SEM-EDX is recommended for a reliable detection.

Salts

Salts are a rather soft residual contaminant, which is why they are classified as uncritical. These particles are typically residues of washing processes or additives of lubricants.

Salts are a rather soft residual contaminant, which is why they are classified as uncritical. These particles are typically residues of washing processes or additives of lubricants.

Organics

Organic particles, such as fibres and plastics, are soft. Due to their size, these particles are becoming increasingly relevant, as they can clog fine holes and filters. Glass fibre reinforced plastics are also critical, because they are highly abrasive, as a consequence of their high glass content.

Organic particles, such as fibres and plastics, are soft. Due to their size, these particles are becoming increasingly relevant, as they can clog fine holes and filters. Glass fibre reinforced plastics are also critical, because they are highly abrasive, as a consequence of their high glass content.

Oils & Fats

Hardness is not considered when it comes to oil and fat impurities. These contaminants occupy component surfaces in form of a film and cause problems during subsequent processing stages, such as painting, anodizing and coating.

Hardness is not considered when it comes to oil and fat impurities. These contaminants occupy component surfaces in form of a film and cause problems during subsequent processing stages, such as painting, anodizing and coating.