The problems that the smallest residual dirt particles can cause were recently experienced by a German car manufacturer: It had to recall numerous vehicles due to malfunctions in the engine. The reason was manufacturing residues consisting of hard particles that lead to capital engine damage – in the worst case to burning cars.

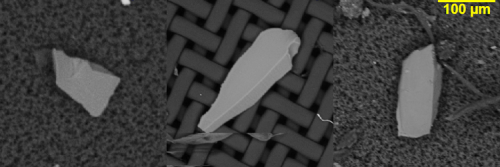

Hard residual dirt particles usually originate from the fine machining of surfaces by glass blasting, vibratory grinding, honing or barrel finishing. These steps are intended to specifically refine components and improve dimensional and shape accuracy. The particles remain on the surface as production residues if they are not adequately cleaned.

Hard particles have an extremely abrasive effect, i.e. they break down other materials, damaging functional layers and surfaces. In addition, hard residual dirt particles can get into the sliding surfaces of bearings and raceways, jamming them and thereby lead to the complete destruction of an engine.

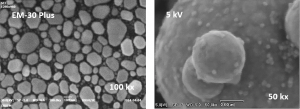

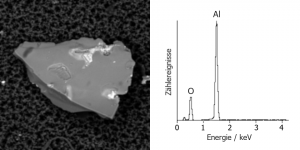

Our team was able to assist the manufacturer by providing the hardness and origin of the production residues of various individual parts of the affected engines with an automatic SEM-EDX microscope of FEI-Aspex brand investigated (see figure). Hard residual dirt particles such as corundum and silicon carbides with a Moh’s hardness > 8 were determined in the crankshaft, connecting rod and cylinder head. For comparison: diamond has a Moh’s hardness of 10.

Find out about the SEM-EDX systems from FEI-Aspex as well as our accredited analysis service.