The identification of metallic particles is an important requirement in cleanliness analysis. In recent years, the light-optical detection of metallic particles has commonly been performed by the means of gloss. On the basis of our laboratory experience, we have found that the light microscopic analysis often leads to incorrect typifications, which can be easily avoided by a material analysis using SEM-EDX.

Light Microscopy Compared to SEM-EDX

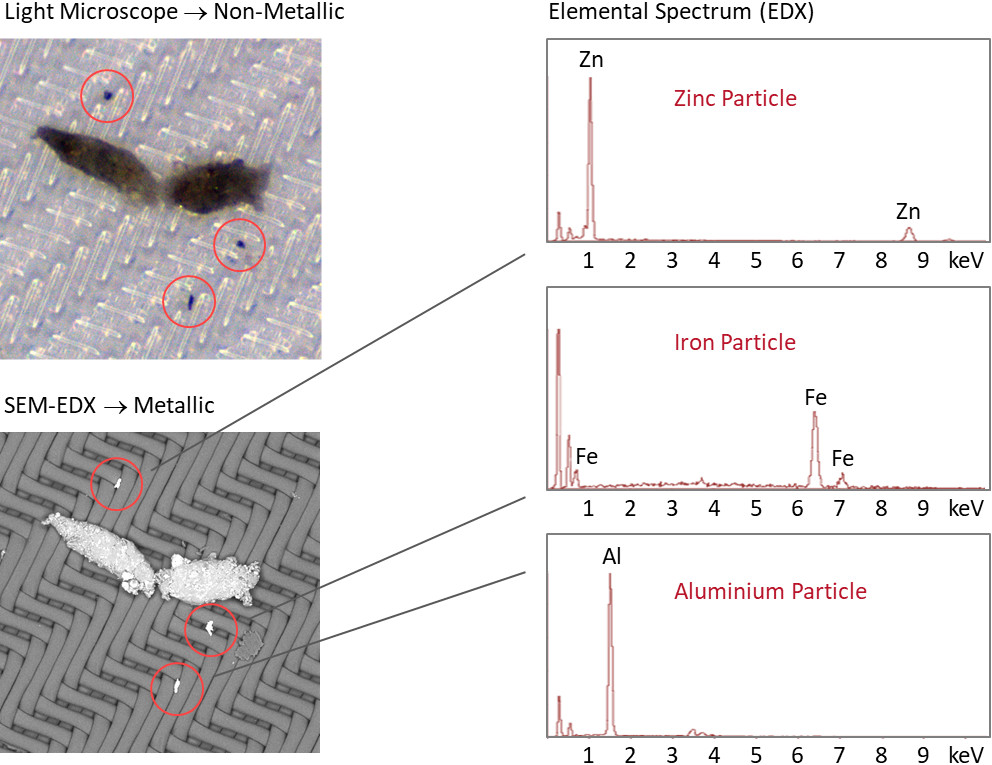

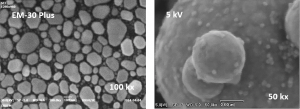

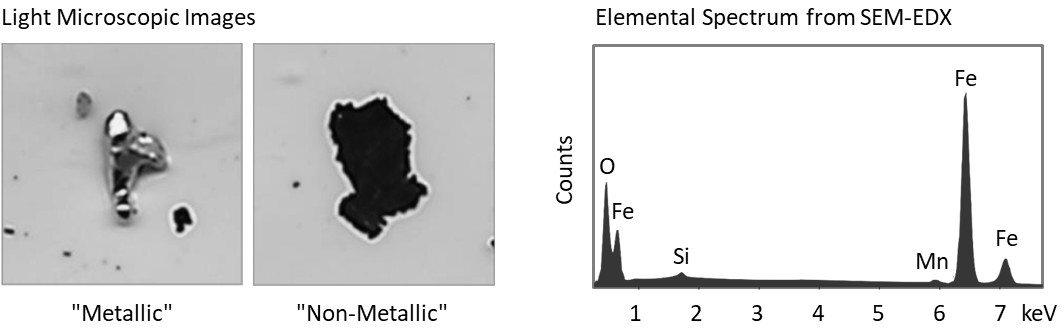

The light-microscopic detection of metallic particles is performed on the basis of light reflection. A particle is classified as metallic if it incorporates shiny spots. In all other cases, the particle is considered to be non-metallic. In SEM-EDX analysis. a particle's X-Ray spectrum is measured, allowing its elemental components to be identified. This information enables a precise material typification.

Do Metallic Particles Really Shine?

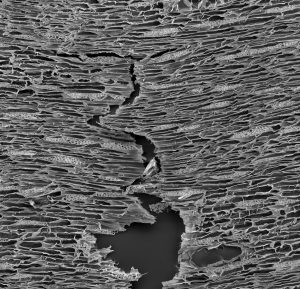

The analysis of reflections requires that metals on a filter membrane actually shine. Since the contaminant particles are exposed to liquids, temperature and friction during component processing, their surface is often non-shiny, but dull or corroded. These metallic particles are erroneously classified as non-metallic by light microscopy. In the following example, three particles (zinc, steel and aluminum) are shown, which have been recognized by light microscopy as non-metallic. However, the SEM-EDX analysis shows the metallic nature of these particles.

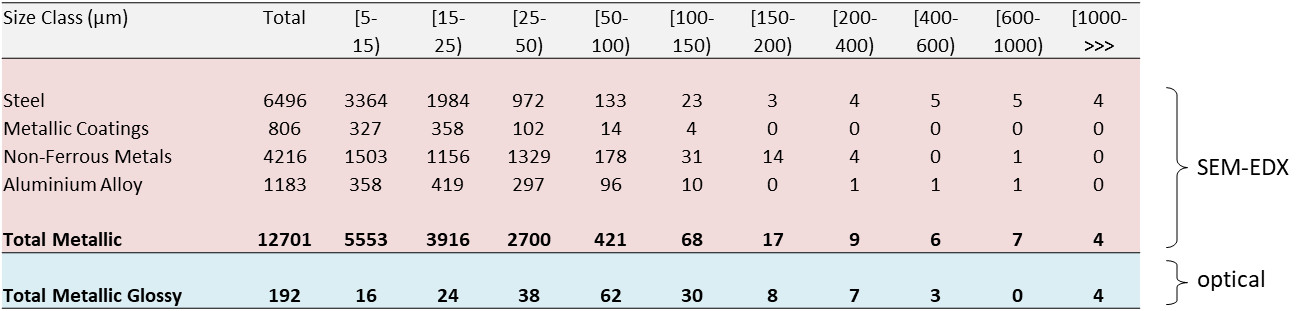

Light Microscopy Underestimates the Quantity of Metallic Particles

The following comparison with SEM-EDX shows just how serious the erroneous typification by light microscopy can be. The membrane as well as the result of optical particle analysis was provided to us by an automotive supplier. The comparison with SEM-EDX was carried out in our accredited test laboratory. In this particular case, less than 1/60 of the actual metal particles were detected by light microscopy.

Our Recommendation to You

In applications where the reliable detection of metallic particles is critical for a component's functionality, e.g. electronical parts, we recommend particle analysis by the means of SEM-EDX. For routine analysis of component cleaning, the optical detection of metals should be completely eliminated and only the total number of particles should be considered instead. Talk to our experts and benefit from our many years of experience.