Coxem has presented a new model of its compact Ion mill CP-8000+. The device supports the standard cutting (“cross-sectioning”) and polishing (“flat milling”) modalities and can be operated intuitively via the integrated touchscreen.

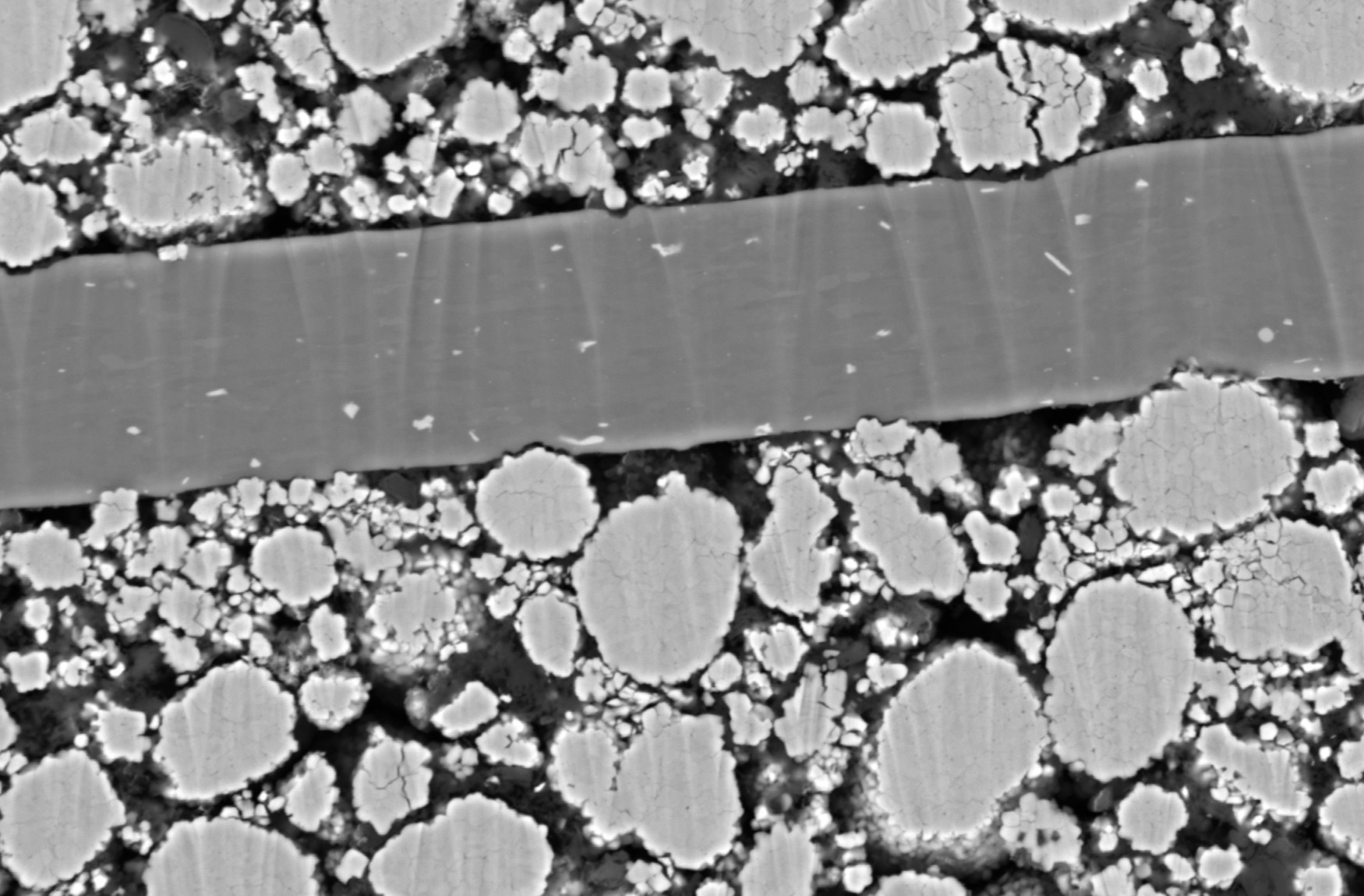

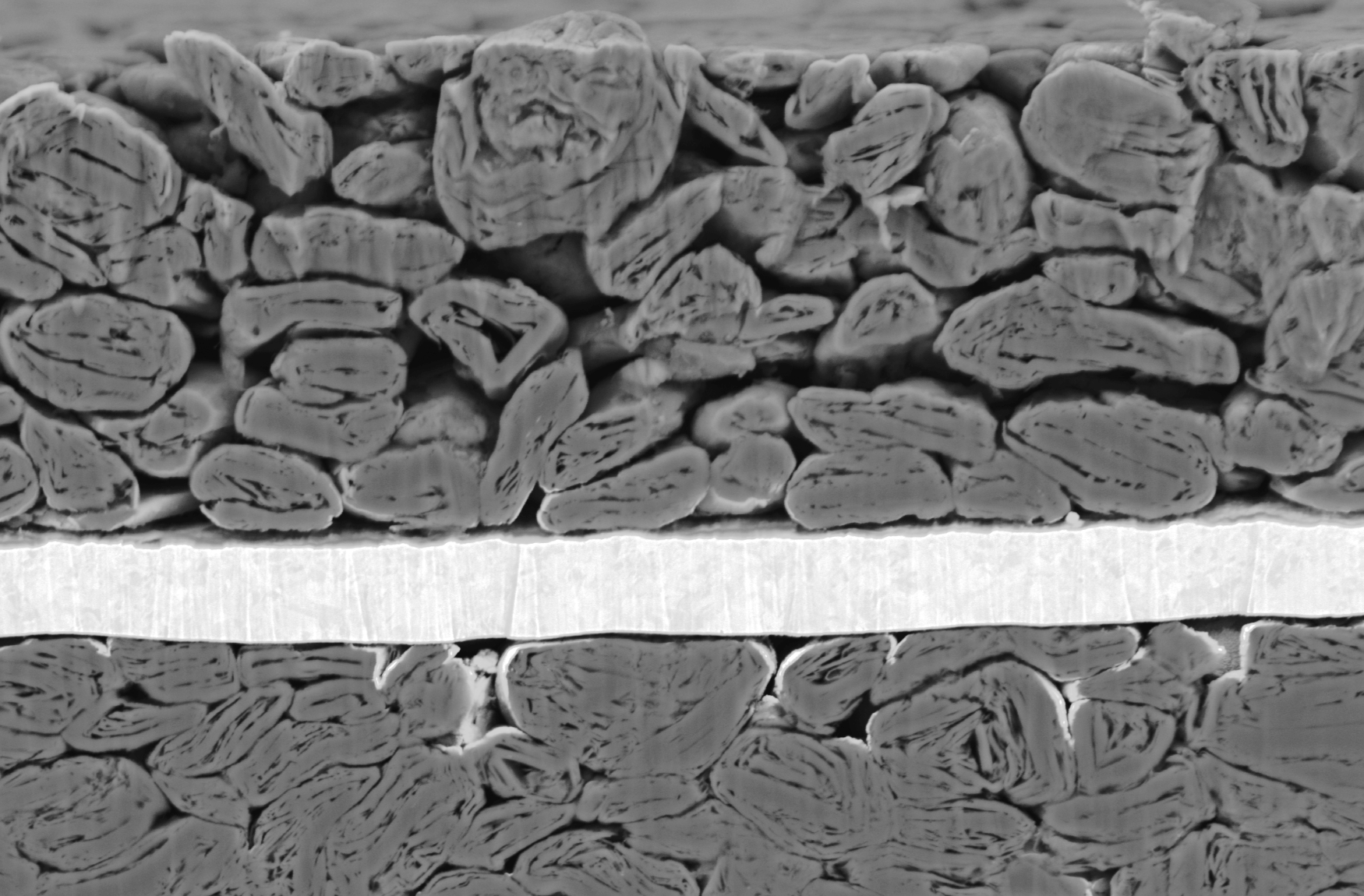

Conventional cutting, breaking, or mechanical polishing can cause surface damage and deformation on delicate samples, which can result in misinterpretation of the microstructure. The CP-8000+ uses an argon ion beam to remove material at the atomic level, producing clean, precise cross-sections. This method is ideal for sample preparation for SEM, EDX and EBSD analyses.

The device utilizes intelligent sample holders that are fixed to the table using a magnetic closure. An HD camera enables live observation of the ion beam etching process and thus increases the safety of target preparation. Individual recipes can be saved in an internal database for later use.

A customer from the battery industry wanted to know more and provided us with cathode and anode material. The preparation effort for a cross section was significantly less than an hour (15 min set-up time & 30 min etching time). The sample was then imaged with a Coxem EM-30N SEM-EDX tabletop device. The results were very convincing and enabled precise layer thickness measurements as well as a reliable assessment of the microstructural structure.

Coxem has presented the functionality and special properties of the compact ion beam etching system CP-8000+ in a video with clear animations.