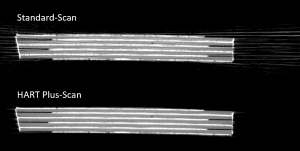

High Aspect Ratio Tomography for Samples with a High Aspect Ratio

For the latest generation of SkyScan micro-CT devices, Bruker has developed a special scan mode for samples with a high aspect ratio. Objects of this type are characterized by a high ratio of length to width and repeatedly pose challenges for users of microtomography.