Quality control in precious metals industry using SEM-EDX

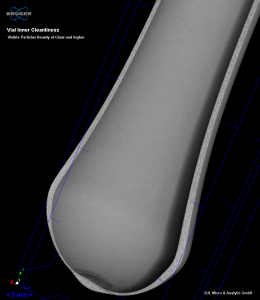

Ceramic crucibles are indispensable in the precious metals industry, but due to the high melting temperatures of some precious metals, they have a limited lifespan and sometimes need to be replaced daily. Each replacement means lost time and additional costs. A customer turned to our accredited testing laboratory to maximize their service life.