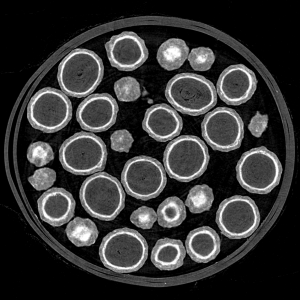

Component cleanliness according to VDA-19 and ISO-16232 is predominantly evaluated using optical measuring systems such as light microscopes or the MicroQuick Particle Scanner However, when optical methods reach their limits, the electron microscope (SEM-EDX) is the measurement system of choice. In addition to the number and size of particles, this technology provides a detailed chemical classification for each individual particle. SEM-EDX analysis is inherently slower than purely optical evaluation, which is why various solutions for accelerated analysis are available.

Correlational Approach

Some measurement systems employ a correlative approach, in which the filter is first evaluated using light optics. The determined particle coordinates are then used to relocate critical particles (e.g., all particles > 100 µm) in an electron microscope. While this method sounds appealing, it has a significant drawback: only particles that are optically distinct from the filter (color contrast) can be targeted. Critical particles, such as abrasive minerals, are easily overlooked and therefore cannot be targeted and detected in the SEM.

Dynamic Beam Control and Real-Time Imaging

To reliably detect all critical particle types (minerals, metals), it is better to analyze the entire filter using SEM-EDX. Speed is crucial here! The manufacturer Thermo Fisher has also recognized this and developed its Phenom ParticleX equipped with various unique features that make the system incomparably fast.

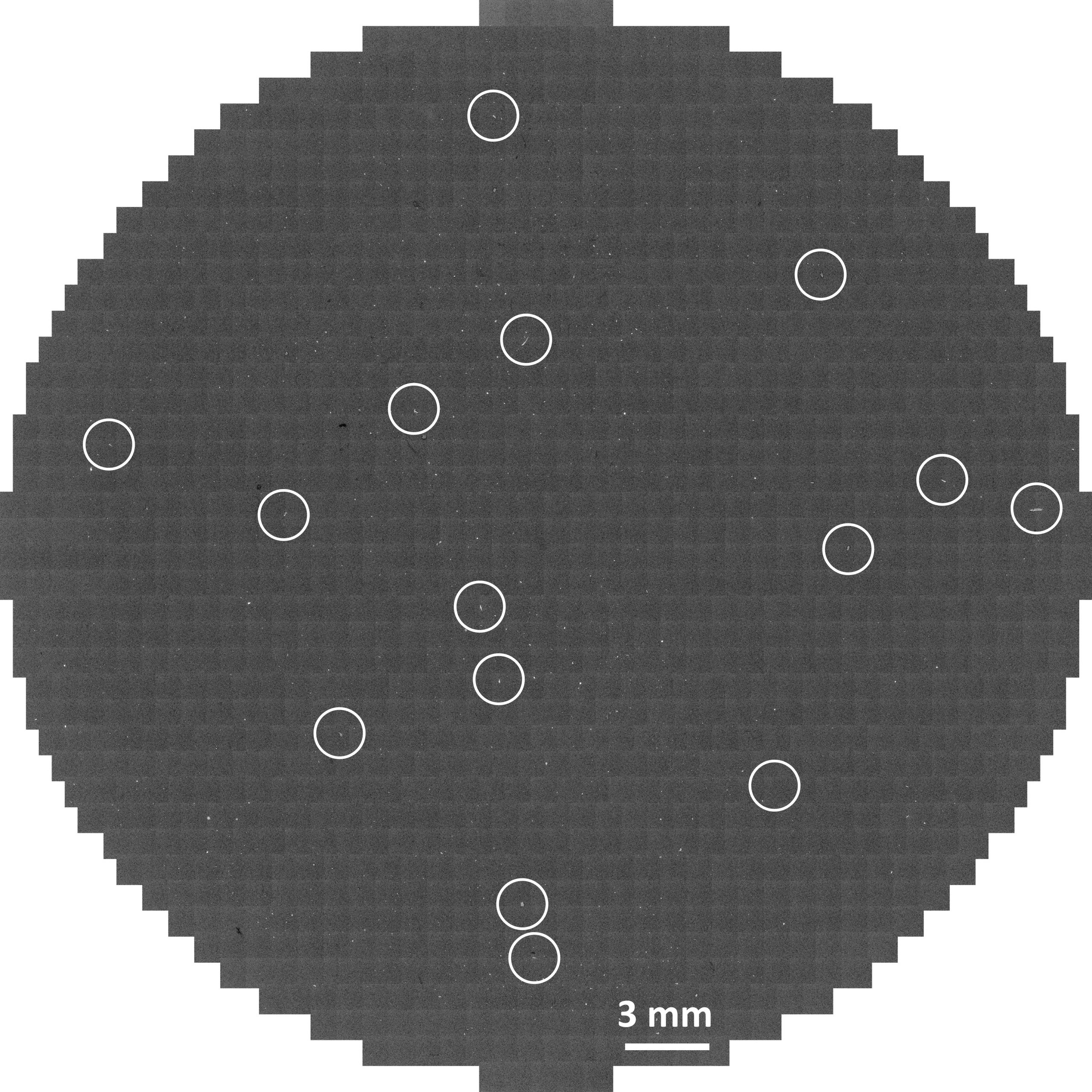

Utilizing a dynamic beam control, each image field is first coarsely scanned point by point with the electron beam to scan the empty areas as quickly as possible. This saves up to 98 % of imaging time. Only when a particle is detected does the system switch to high-resolution measurement mode. In combination with the CeB6 cathode (10 times higher brilliance compared to tungsten), this speed advantage is further increased, as the following example shows.

Using the ParticleX, we were able to achieve a complete count of all particles > 100 µm (including EDX and reporting) on a customer's moderately contaminated 47 mm filter in just 15 minutes. We demonstrate the simple operation and the process in a video:

The speed advantage is also evident in analyses of smaller particle sizes.

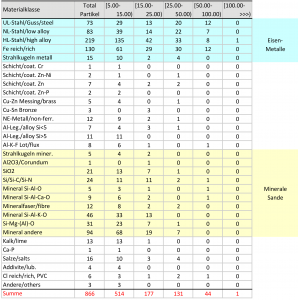

| Particles larger than | Particle count analyzed | Duration including setup time |

|---|---|---|

| 100 µm | 37 | 17 min |

| 50 µm | 211 | 21 min |

| 25 µm | 2220 | 51 min |

| 10 µm | 13127 | 2 h 48 min |

These results show that a correlational approach in the standard analysis range (> 50 µm) usually does not result in any time savings. Therefore, for critical particle types (minerals, metals), we always recommend a complete filter analysis using SEM-EDX.