Guide to SEM-EDX for buyers and interested parties

In response to many requests from our customers, we have developed a guide to help buyers choose a suitable system with practical advice and technical information.

In response to many requests from our customers, we have developed a guide to help buyers choose a suitable system with practical advice and technical information.

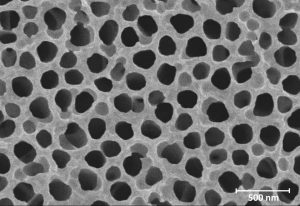

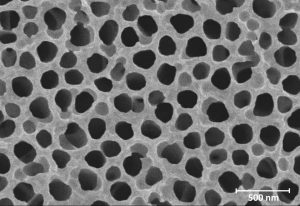

When it comes to component cleanliness, the hardest particles cause the most damage. The difficulty, however, is finding these killer particles because they can be so small that they cannot be seen with a light microscope.

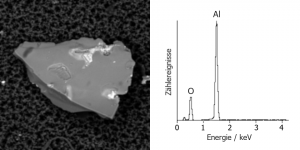

The identification of metallic particles is an important requirement in cleanliness analysis. In recent years, the light-optical detection of metallic particles has commonly been performed by the means of gloss. On the basis of our laboratory experience, we have found that the light microscopic analysis often leads to incorrect typifications, which can be easily avoided by a material analysis using SEM-EDX.

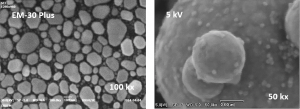

The Korean company Coxem has developed economical tabletop devices for SEM-EDX analysis that impress with excellent resolution. This new product series is now also available in Germany via RJL Micro & Analytic. Customers benefit from our proven support and technical service.

Bearing shells have the function of rolling and supporting rolling elements. In four-stroke engines, for example, the connecting rod that connects the piston to the crankshaft rotates in a bearing. This is lubricated with oil, which reduces friction and thus wear. However, the lubricant contains various residual contaminant particles that can become lodged in the bearing shell.

Distilled water has many uses in everyday life, for example as coolant in cars or in steam irons. It has the reputation of being purer than tap water, which is why distilled water is also used for cleanliness analysis in the laboratory. Residues in the water would contaminate the samples during analysis and distort the results.