Guide to SEM-EDX for buyers and interested parties

In response to many requests from our customers, we have developed a guide to help buyers choose a suitable system with practical advice and technical information.

In response to many requests from our customers, we have developed a guide to help buyers choose a suitable system with practical advice and technical information.

When it comes to component cleanliness, the hardest particles cause the most damage. The difficulty, however, is finding these killer particles because they can be so small that they cannot be seen with a light microscope.

Yesterday we had a working visit from the German Accreditation Body (DAkkS), who audited our management system for ISO-17025 accreditation. Monitoring of this type is carried out by the DAkkS at regular intervals, and our processes are put through their paces.

With the new SkyScan 1273, Bruker presents a high-resolution X-Ray 3D microscope for large samples in table top format. XXL objects up to 50 cm x 30 cm can be accommodated in the measuring chamber, the largest field of view is 25 cm x 25 cm.

The revised quality standard ISO-16232 “Road vehicles-Cleanliness of components of fluid circuits” was published in December 2018. This international standard for the cleanliness analysis of automotive parts corresponds to the regulations of VDA 19.1, in the development of which RJL Micro & Analytic GmbH played a key role.

Our customer Dr. Arnold Staniczek and his team from the State Museum of Natural History in Stuttgart recently achieved a scientific sensation.

A central requirement in the production of pharmaceutical products is the avoidance of visible foreign particles. Our testing laboratory has developed innovative yet simple methods to reliably quantify foreign particles in pharmaceutical powders.

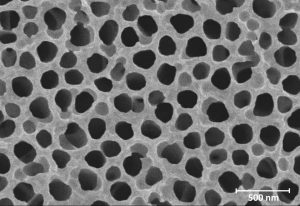

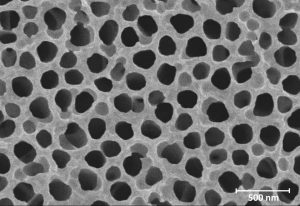

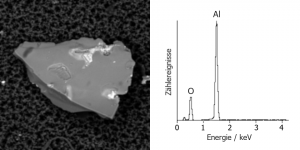

The identification of metallic particles is an important requirement in cleanliness analysis. In recent years, the light-optical detection of metallic particles has commonly been performed by the means of gloss. On the basis of our laboratory experience, we have found that the light microscopic analysis often leads to incorrect typifications, which can be easily avoided by a material analysis using SEM-EDX.

The new nano-CT from the SkyScan family impresses with its excellent optical resolution of less than 0.5 µm and a wide range of applications.