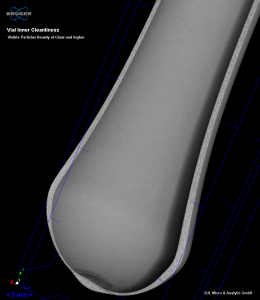

Ceramic crucibles are indispensable in the precious metals industry, but due to the high melting temperatures of some precious metals, they have a limited lifespan and sometimes need to be replaced daily. Each replacement means lost time and additional costs. With the goal of maximizing their service life, a customer turned to our accredited testing laboratory.

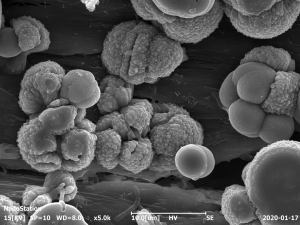

It is known that with increasing service life, particles can detach from the inner wall of the crucible and become embedded in the precious metal as foreign inclusions. Utilizing automated foreign inclusion analysis by SEM-EDX, we have examined this process statistically and quantitatively with the Phenom ParticleX .

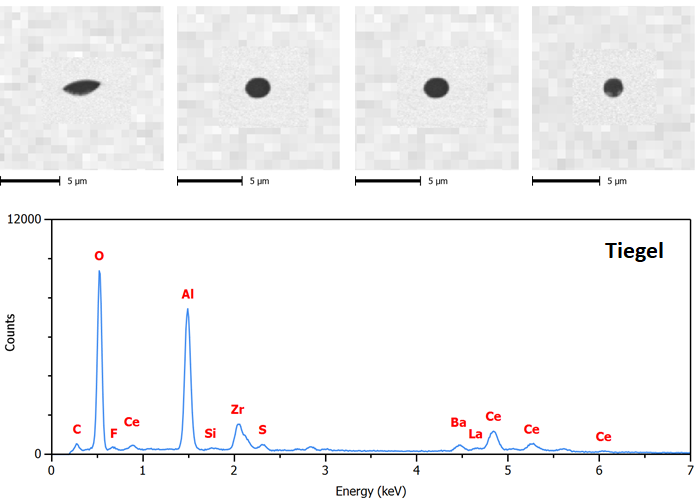

One aspect of this analysis was particularly tricky. The EDX energy lines of the crucible material showed significant overlap with those of the precious metal, making robust quantification of the inclusions difficult. By specifically adapting the measurement routine to the customer's specific materials, the problem was resolved.

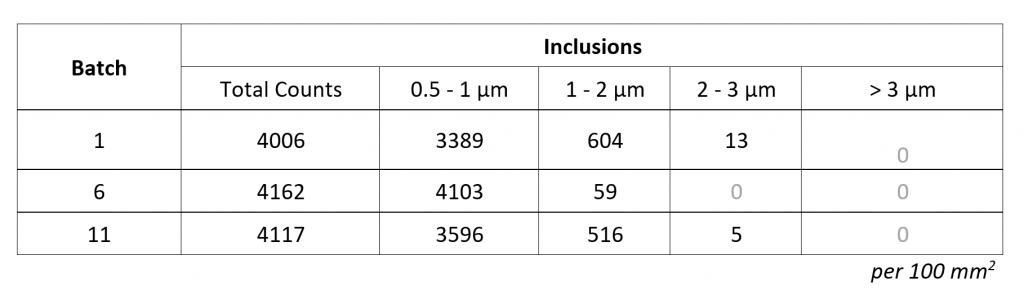

Previously, the crucible was replaced after every 11 batches, so that one batch was examined at the beginning, middle, and end of the crucible's service life. The customer was pleased to see that no inclusions larger than 3 µm were observed during the crucible's service life and that no fluctuations were discernible over the entire service life.

This suggests that the crucibles can be used beyond 11 batches, and that a replacement will only be necessary at a later stage. Further investigations are needed to determine this point in time more precisely.