Sand in the Gearbox – Abrasive Minerals Invisible in Contaminant Particles?

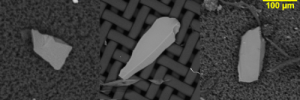

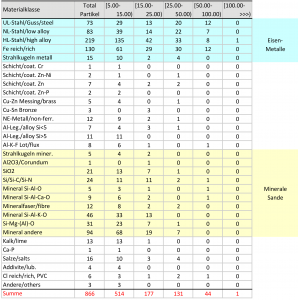

It is often surprising for our customers when we find hard mineral particles on their components during technical cleanliness analysis. Customers ask: "How can that be? We didn't find anything in our own cleanliness tests." The contamination of hard minerals is so important, because these particles have an abrasive effect and thus massively damage mechanical systems such as gears and motors.