ONLINE BASIC COURSE

Cleanliness Analysis According to VDA 19.1 & ISO-16232

Part 4

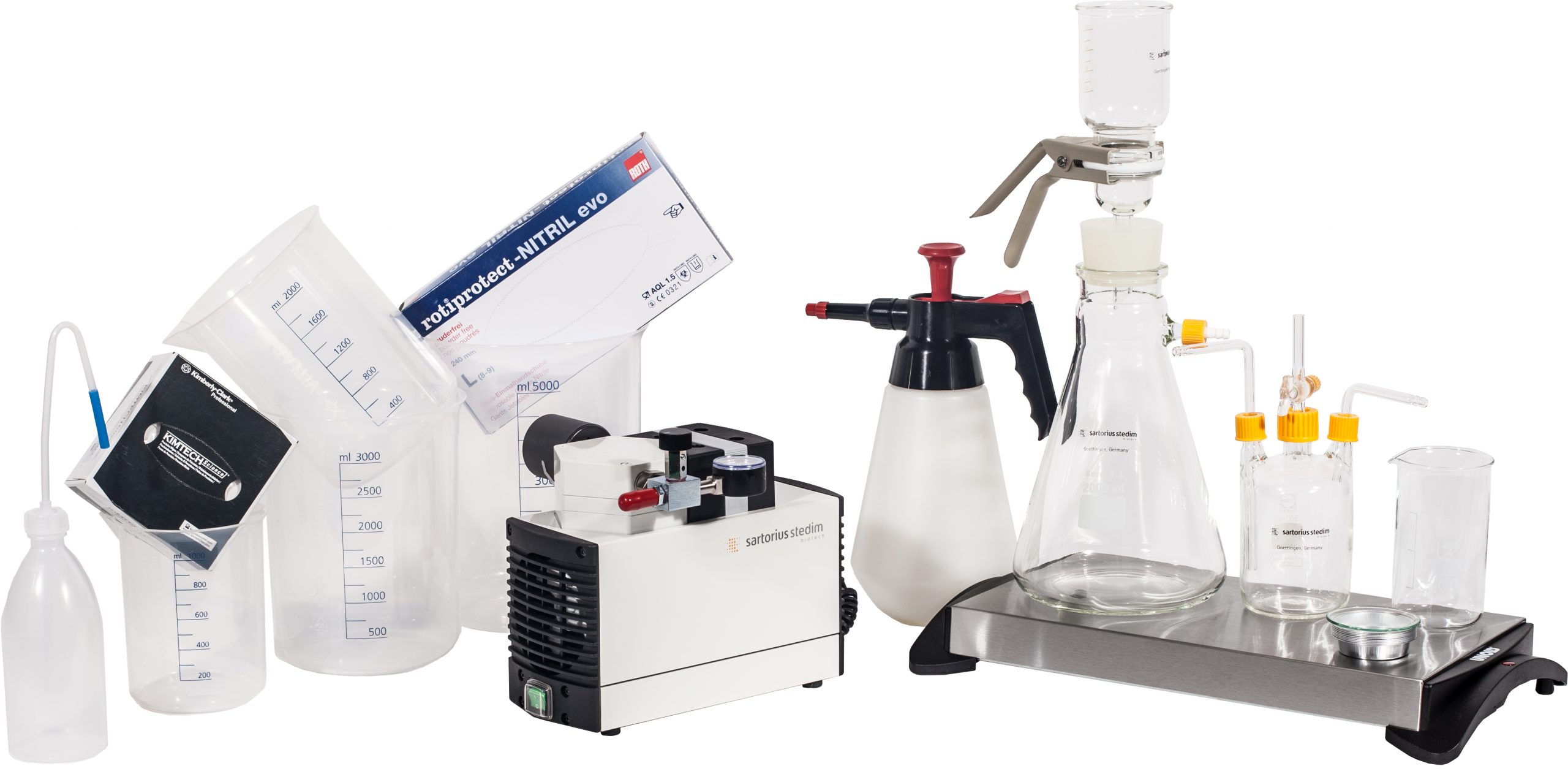

Equipment for Extraction and Filtration

The extraction and filtration of particles is typically achieved by either of the two following technical setups.

1. Sprayer with hand pump for extraction in laboratory, ultrasonic bath and a vacuum filtration unit made of glass:

This is a simple and economic approach. It is well suited for small- to medium-sized components that can be extracted in a simple beaker or small receptacle.

2. Integrated extraction cabinet with sprayer, ultrasound, filtration and regeneration in one system:

Manual labor for extraction is lower using the cabinet when compared to the laboratory system, but costs are distinctively higher.

Navigator

Online Basic Course

- (1) Standardized Analysis of Component Cleanliness

- (2) Particle Extraction from Component Surface

- (3) Filtration of the Residual Particles

- (4) Equipment for Extraction and Filtration

- (5) Gravimetric Analysis of Particle Mass

- (6) Scanner and Microscope for Standardized Analysis

- (7) Optical Analysis of Residual Contaminant Particles

- (8) Particle Analysis from 50 Microns

- (9) Presentation of Particle Cleanliness

- (10) Residual Contaminant Analysis Using SEM-EDX

- (1) Standardized Analysis of Component Cleanliness

- (2) Particle Extraction from Component Surface

- (3) Filtration of the Residual Particles

- (4) Equipment for Extraction and Filtration

- (5) Gravimetric Analysis of Particle Mass

- (6) Scanner and Microscope for Standardized Analysis

- (7) Optical Analysis of Residual Contaminant Particles

- (8) Particle Analysis from 50 Microns

- (9) Presentation of Particle Cleanliness

- (10) Residual Contaminant Analysis Using SEM-EDX