ONLINE BASIC COURSE

Cleanliness Analysis According to VDA 19.1 & ISO-16232

Part 10

Residual Contaminat Analysis Using SEM-EDX

Amongst the numerous methods of extended particle analysis described in VDA 19.1, in particular automated scanning electron microscopy with X-Ray element analysis (SEM-EDX) is used for the identification of residual particles. This method has proven itself particularly useful for to detection of small grinding particles, which have a high damage potential due to their abrasiveness.

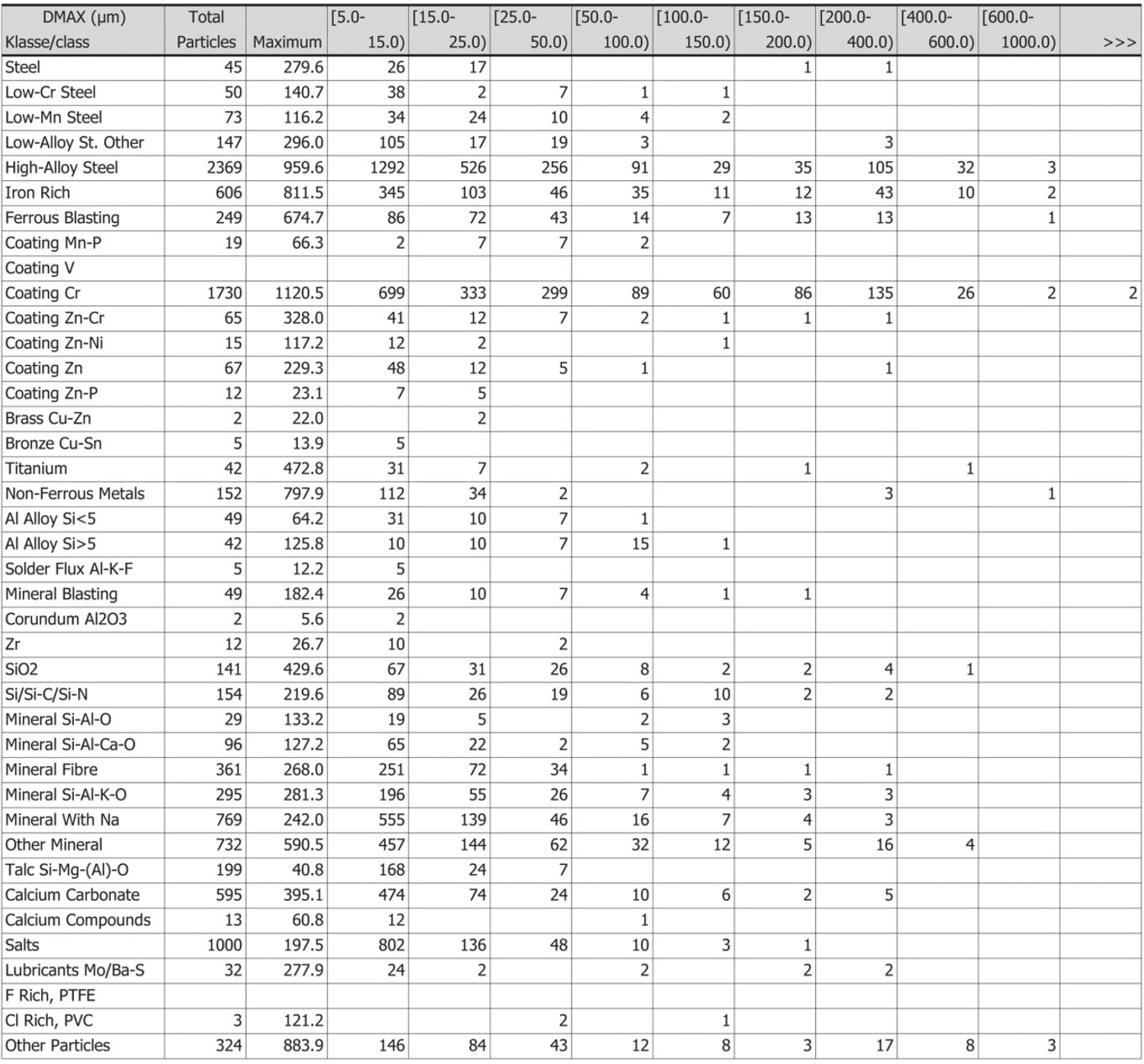

The Aspex Explorer is an instrument specifically designed for particle analysis in the field of technical cleanliness. The system is able to fully automatically distinguish a large number of material classes for particles up to a size of less than 1 µm (see illustration). Cleanliness laboratories that do not want to invest in a SEM-EDX system can meet their analytical needs in our Accredited Test Laboratory.

Material typification and particle size histogram measured by an automated SEM-EDX system

Navigator

Online Basic Course

- (1) Standardized Analysis of Component Cleanliness

- (2) Particle Extraction from Component Surface

- (3) Filtration of the Residual Particles

- (4) Equipment for Extraction and Filtration

- (5) Gravimetric Analysis of Particle Mass

- (6) Scanner and Microscope for Standardized Analysis

- (7) Optical Analysis of Residual Contaminant Particles

- (8) Particle Analysis from 50 Microns

- (9) Presentation of Particle Cleanliness

- (10) Residual Contaminant Analysis Using SEM-EDX

- (1) Standardized Analysis of Component Cleanliness

- (2) Particle Extraction from Component Surface

- (3) Filtration of the Residual Particles

- (4) Equipment for Extraction and Filtration

- (5) Gravimetric Analysis of Particle Mass

- (6) Scanner and Microscope for Standardized Analysis

- (7) Optical Analysis of Residual Contaminant Particles

- (8) Particle Analysis from 50 Microns

- (9) Presentation of Particle Cleanliness

- (10) Residual Contaminant Analysis Using SEM-EDX