ONLINE BASIC COURSE

Cleanliness Analysis According to VDA 19.1 & ISO-16232

Part 3

Filtration of the Residual Particles

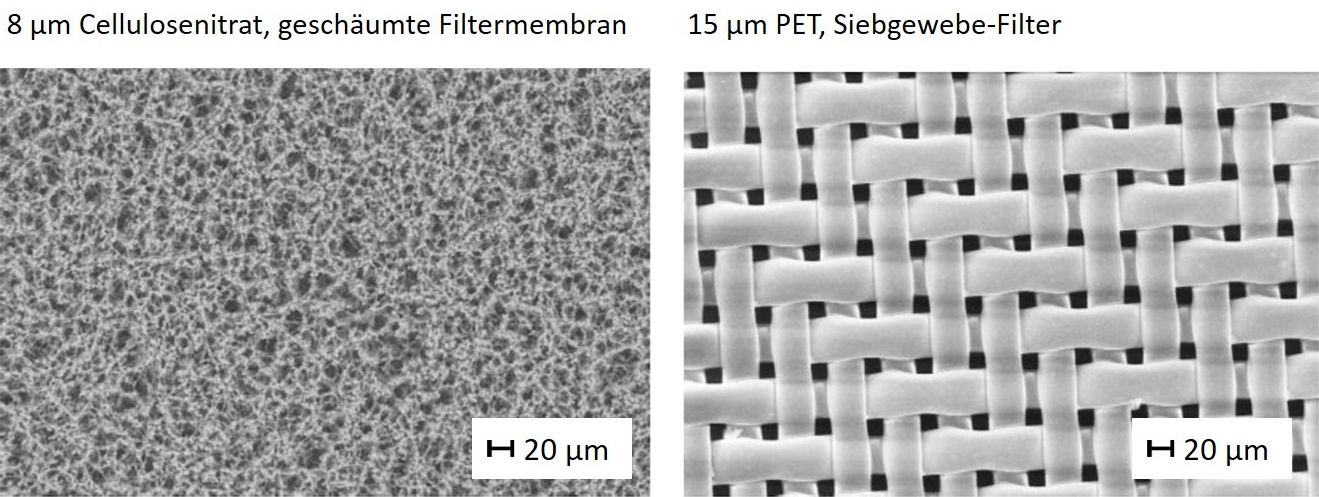

The particles trapped in the extraction fluid are prepared by vacuum filtration onto the membrane. In order to choose an optimal filter, the filter's chemical stability against the extraction fluid as well as its pore size have to be considered. Foamed and meshed membranes are available (see picture).

Structure of foamed and meshed membrane (source VDA-19.1).

The structure of a foamed filter corresponds to that of a sponge, achieving a highly efficient filtration. Therefore, foamed membranes are particularly well suited for determine the particle mass. Furthermore, foamed filters are available with pore diameters down to the submicrometer scale, enabling a reliable detection of even the smallest particles.

On the other hand, foamed filters tend to form a dark background during filtration if the fluid contains a significant level of highly fine-grained particles or carbon black. In this case, a proper analysis of the particles is often not possible due to poor contrast. Meshed polyethylene (PET) membranes with a pore size of 5 μm are thus recommended as standard in VDA volume 19.1. Meshed membranes rarely show a dark background after filtration, which is why PET mesh fabrics are highly suitable for optical analysis. In addition, the material is chemically stable against most extraction fluids. Since mesh filters are not available with pores smaller than 5 microns, the detection is limited to particles larger than 25 to 50 microns. If necessary, the two types of membranes can be combined into a single filter cascade.

Navigator

Online Basic Course

- (1) Standardized Analysis of Component Cleanliness

- (2) Particle Extraction from Component Surface

- (3) Filtration of the Residual Particles

- (4) Equipment for Extraction and Filtration

- (5) Gravimetric Analysis of Particle Mass

- (6) Scanner and Microscope for Standardized Analysis

- (7) Optical Analysis of Residual Contaminant Particles

- (8) Particle Analysis from 50 Microns

- (9) Presentation of Particle Cleanliness

- (10) Residual Contaminant Analysis Using SEM-EDX

- (1) Standardized Analysis of Component Cleanliness

- (2) Particle Extraction from Component Surface

- (3) Filtration of the Residual Particles

- (4) Equipment for Extraction and Filtration

- (5) Gravimetric Analysis of Particle Mass

- (6) Scanner and Microscope for Standardized Analysis

- (7) Optical Analysis of Residual Contaminant Particles

- (8) Particle Analysis from 50 Microns

- (9) Presentation of Particle Cleanliness

- (10) Residual Contaminant Analysis Using SEM-EDX